- Contact Person : Mr. Chow Robin

- Company Name : Zhongyou Kingsun International Economic & Trading Co., Ltd.

- Tel : 0086-21-60405576

- Fax : 0086-21-60405590

- Address : Shanghai,Shanghai,Huangxing Road 2077, Yangpu

- Country/Region : China

- Zip : Zip 200433

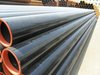

300mm diameter steel pipe

1. Standards

1.1 Line PipesAPI 5L PSL1/PSL 2 Line Pipe: Gr. B X42, X46, X52, X56, X60, X65, X70, X80/BM.X42M,X46M,X52M,X60M,X65M,X70,X80MISO 3183-1/2 Petroleum and Natural Gas Industries-Steel Pipe for Pipelines Transportation System-L240M,L290M,L320M,L360M,L390M,L415M,L450M,L485M,L555M,L690MISO 3183-3 Petroleum and Natural Gas Industries Steel Pipe for Pipelines Transportation System -L245NC / L245NCS,L290NC / L290NCS, L360NC / L360NCS, L290MC / L290MCS, L360MC / L360MCS, L415MC / L415MCS, L450MC / L450MCS, L485MC / L485MCS, L555MC AS2885 Pipelines-Gas and liquid petroleum Part 1: Design and Construction BS 3601-1 Carbon steel pipes and tubes with specified room temperature properties for pressure purposes BS 3602-2 Specification for steel pipes and tubes for pressure purposes: carbon and carbon manganese steel with specified elevated temperature properties. Part 2: Submerged arc welded tubes BS 6323 Seamless and welded steel tubes for automobile mechanical and general engineering purposes. Part 1: General requirements. Part 7: Specific requirements for submerged arc welded steel tube CSA Z245.1 Steel PipeDIN 2470-1 Steel gas pipelines for permissible service pressures up to 16 bar DIN 2470-2 Steel gas pipelines for permissible service pressures exceeding 16 bar EN 10208-1:2009, Steel pipes for pipelines for combustible fluids - Technical delivery conditions - Part 1: Pipes of requirement class A.EN 10208-2:2009, Steel pipes for pipelines for combustible fluids – Technical delivery conditions – Part 2: Pipes of requirement class B. L245MB,L290MB,L320MB,L360MB,L390MB,L415MB,L450MB, L485MB,L555MBEN 10208-3 Non alloy and alloy fine grain steel tubes EN ISO 21329:2004, Petroleum and natural gas industries - Pipeline transportation systems - Testing procedures for mechanical connections (ISO 21329:2004). ISO 10543:1993, Seamless and hot-stretch-reduced welded steel tubes for pressure purposes - Full peripheral ultrasonic thickness testing. ISO 21329:2004, Petroleum and natural gas industries - Pipeline transportation systems - Testing procedures for mechanical connections. - 1st edition. EEMUA Publ 203:2004, Guide to the Application of ISO 3183 Parts 2 (1996) and 3 (1999) Petroleum and Natural Gas Industries - Steel Pipes for Pipelines - Technical Delivery Conditions. NACE MR 0175/ISO 15156-2 Petroleum and Natural Gas Industries – Materials for Use in H2S Containing Environments in Oil and Gas Production. Part 2. Cracking resistant Carbon and Low Alloy Steels, and the Use of Cast Irons. NACE TM 0177 Laboratory Testing of Metals for Resistance to Sulfide Stress Cracking in Hydrogen Sulfide (H2S) Environments NACE TM 0284 Standard Test Method - Evaluation of Pipeline and Pressure Vessel Steels for Resistance to Hydrogen-Induced Cracking DEP 31.40.20.30-Gen LINEPIPE FOR USE IN OIL AND GAS OPERATIONS UNDER NON-SOUR CONDITIONS(AMENDMENTS/SUPPLEMENTS TO API SPEC 5L) DEP 31.40.20.31-Gen LINEPIPE FOR USE IN OIL AND GAS OPERATIONS UNDER SOUR CONDITIONS(AMENDMENTS/SUPPLEMENTS TO API SPEC 5L) DEP 31.40.20.35-Gen Line pipe for non-critical service (amendments/supplements to ISO 3183-1) DEP 31.40.20.37-Gen Linepipe for critical service (amendments/supplements to ISO 3183-3) DEP 31.40.40.38-Gen Hydrostatic pressure testing of new pipelines DEP 31.40.60.11-Gen Pipeline leak detection DEP 31.40.60.12-Gen Pipeline Repairs (supplements to ANSI/ASME B31.4 and B31.8) DEP 61.40.20.30-Gen Welding of pipelines and related facilities (amendments/supplements to ANSI/API STD 1104) DEP 31.40.50.30-Gen Precommissioning of pipelines Plain end seamless hot rolled tubes - NF A 49-112Seamless hot-rolled steel tubes - GOST 8731-74 GOST 8732-78High-performance seamless circular - EN 10220 DIN 1630Seamless circular unalloyed steel tubessubject to special requirements - EN 10220 DIN 1629GOST 20295:1985, Steel welded pipes for main gas-and-oil pipelines Specifications- K56,K60,K65GOST R ISO 10124:1999, Seamless and welded (except submerged arc-welded) steel tubes for pressure purposes - Ultrasonic testing for the detection of laminar imperfections. GOST R ISO 10332:1999, Seamless and welded (except submerged arc-welded) steel tubes for pressure purposes. Ultrasonic testing for the verification of hydraulic leak-tightness. GOST R ISO 10543:1999, Seamless and hot-stretch-reduced welded steel tubes for pressure purposes - Full peripheral ultrasonic thickness testing. GOST R ISO 3183:2010, Petroleum and natural gas industries - Steel pipe for pipeline transportation systems. - 2nd edition.IPS-M-PI-190 Material And Equipment Standard for Line PipeKOC-MP-018 KOC Standard for Seamless Pipe to API 5LKOC-MS-001 Part 1 Kuwait Material Specification Line Pipe for Sour ServiceNRF-001-Pemex-2007 Steel Piping for Hydrocarbon Collections and TransportationRP 43-1 Onshore Transmission Pipelines to BS 8010 API 5L: TUBOS PARA CONDUÇÃO DE PRODUTOS PETROLÍFEROS.API 5LX: TUBOS PARA CONDUÇÃO DE PRODUTOS PETROLÍFEROS COM EXIGÊNCIAS ESPECIAIS1.2 Pipe for General Uses BS 2059 Part I & II Gr. 320, Gr. 360BS 3601 Steel Pipe and Tubes for Pressure Proposes Carbon Steel: Ordinary Duties- Gr. 360,Gr. 430, EN 10220 Seamless and welded steel tubes. EN 10224 Steel pipes, joints and fittings for the conveyance of aqueous liquids including potable water 1.3 Structural Pipe ASTM A53 A/B 1.4 Submarine (Offshore) Pipeline SystemDNV OS-F101 Submarine Pipeline Systems-SAWL 245,SAWL290,SAWL 320,SAWL 360,SAWL 415,SAWL 450,SAWL 485,SAWL 555,AS 2885-1:1997AS 2885-2:2002, AS 2885-3:2001, AS 2885-4:2003, AS/NZS 2885-5:2002, ASME B31.4:1998, ASME B31.8:2000,BS 8010-1:1989, BS 8010-2.8:1992,BS 8010-3:1993, CSA-Z245.1

2. Coating Specifications2.1 External Coating2.1.1 External Epoxy CoatingAPI RP 5L2 Recommended Practice for Internal Coating of Line Pipe for Non-Corrosive Gas Transmission Service.CAN/CSA-Z245.20 Standard for External Fusion Bond Epoxy Coating for Steel PipeAS 3862 Standard Specification for External Fusion-Bonded Epoxy Coating for Steel PipesAWWA C210 Standard for Liquid-Epoxy Coating Systems for the Interior and Exterior of Steel Water Pipelines AWWA C213 Standard for Fusion Bonded Epoxy Coating for the Interior and Exterior of Steel Water Pipelines.DEP 31.40.30.32-Gen TECHNICAL SPECIFICATION FOR EXTERNAL FUSION-BONDED EPOXY POWDER COATINGFOR LINE PIPENFA 49-710 Standard Specification for External FBE layered CoatingISO 21809-2:2007, Petroleum and natural gas industries-External coatings for buried or submerged pipelines used in pipeline transportation systems-Part 2: Fusion-bonded epoxy coatingsNACE RP0394 – National Association of Corrosion Engineers Standard Recommended Practice, Application, Performance, and Quality Control of Plant Applied, Fusion Bonded Epoxy External Pipe Coating.NACPA 12-78 – National Association of Pipe Coating Applicators External Application Procedure for Plant Applied fusion Bonded Epoxy (FBE) to Steel Pipe.SAES-H-002 Internal and External Coatings for Steel Pipelines and Piping09-SAMSS-089 Shop-Applied External FBE Coating 09-SAMSS-091 Shop-Applied Internal FBE Coatings 2.1.2 Polyethylene CoatingCAN/CSA Z245.21 External Polyethylene Coating for Pipe DIN 30670 Polyethylene Sheathing of Steel Tubes and of Steel Shaped Fittings NFA 49-710 External Three-Layer Polyethylene Based Coating, Application by ExtrusionDNV-RP-F106 Factory Applied External Pipeline Coatings For Corrosion Control AS/NZS 1518 External Extruded High-Density Polyethylene Coating System for PipesISO/DIS 21809-1 Petroleum and natural gas industries -- External coatings for buried or submerged pipelines used in pipeline transportation systems - Part 1: Polyolefin coatings (3- layer PE and 3- layer PP)ISO 21809-4:2009, Petroleum and natural gas industries -External coatings for buried or submerged pipelines used in pipeline transportation systems-Part 4: Polyethylene Coatings (2-layer PE)DEP 31.40.30.31-Gen. TECHNICAL SPECIFICATION FOR EXTERNAL POLYETHYLENE AND POLYPROPYLENE COATING FOR LINE PIPE IPS-G-TP-335 Material and Construction Standard for Three Layer Polyethylene Coating SystemNFA 49-710 External 3 layer Polyethylene CoatingPETROBRAS' ET-200.03 Engineering Specification ("Piping Materials for Production and Process Facilities") for using low density linear polyethylene in carbon steel piping, as to appendix 13 of such specification.09-SAMSS-113 External Renovation Coating for Buried Pipelines and Piping (APCS-113) UNI 9099-DIN 30670 Polyethylene Coating Applied by Extrusion2.1.3 Polypropylene CoatingDIN30678 Polypropylene Sheathing of Steel Tubes and of Steel Shaped FittingsEN 10286 Steel tubes and fittings for onshore and offshore pipelines –External three layer extruded polypropylene based coatings.NFA 49-711 External Three-Layer Polypropylene Based Coating, Application by Extrusion09-SAMSS-114 Shop-Applied Extruded, Three-Layer Polypropylene External Coatings for Line Pipe 2.1.4 Polyurethane CoatingAWWA C222-99: Polyurethane Coatings for the Interior and Exterior of Steel Water Pipe and FittingsBS 5493- Polyurethane CoatingDIN 30677.2 polyurethane Insulation of the fittingsEN 10290- External Liquid Applied Polyurethane Coatings2.1.5 Polyolefin CoatingAWWA C225-03: Fused Polyolefin Coating Systems for the Exterior of Steel Water PipelinesAWWA C215-99: Extruded Polyolefin Coatings for the Exterior of Steel Water PipelinesAWWA C216-00 Standard for Heat-Shrinkable Cross-Linked Polyolefin Coatings for the Exterior of Special Sections, Connections, and Fitting for the Steel Water PipelinesAWWA C224 - 01: Two-layer Nylon-11 Based Polyamide Coating System for Interior and Exterior of Steel Water Pipe and FittingsAWWA C225 - 03: Fused Polyolefin Coating Systems for the Exterior of Steel Water Pipelines2.1.6 Tape CoatingISO 21809-3:2008, Petroleum and natural gas industries-External coatings for buried or submerged pipelines used in pipeline transportation systems-Part 3: Field joint coatingsAWWA C209-00: Standard for Cold-Applied Tape Coatings for the Exterior of Special Sections, Connections, and Fittings for Steel Water PipelinesAWWA C214-00 Standard for Tape Coating Systems for the Exterior of the Steel Water Pipelines AWWA C217-99 Standard for Cold-Applied Petrolatum Tape and Petroleum Wax Tape Coatings for the Exterior for Special Sections, Connections, and Fittings for Buried/Submerged Steel Water Pipelines AWWA C218-02 Standard for Coating the Exterior of Aboveground Steel Water Pipelines and Fittings AWWA C224-01: Two-layer Nylon-11 Based Polyamide Coating System for Interior and Exterior of Steel Water Pipe and Fittings EN 12068 - DIN 30672 STANDARD-POLYETHYLENE SELF ADHESIVE TAPES2.1.7 Bitumen Coating DIN 30673 Bitumen coatings and linings for steel pipes, fittings and vessels.2.1.8 Coal-Tar Enamel CoatingAWWA C-203 Coal-Tar Protective Coatings and Linings for Steel Water Pipelines-Enamel and Tape-Hot-AppliedAWWA C205 Cement Mortar Protective Lining and Coating for Steel Water Pipe - 4 inch (100 mm) and Larger- Shop Applied 2.1.9 Concrete Weighted CoatingDNV-OS-F101 Submarine Pipeline SystemASTM C171 Specification for Sheet Material for Coating ConcreteBS EN 12620 Aggregates for ConcreteISO 21809-5:2009, Petroleum and natural gas industries -External coatings for buried or submerged pipelines used in pipeline transportation systems - Part 5:External concrete coating. ASTM C42 Standard Test Method for Obtaining and Testing Drilled Cores and Sawed Beams of Concrete ASTM C642 Standard Test Method for Specific Gravity, Absorption and Voids in Hardened Concrete ASTM C87 Standard Test Method for Effect of Impurities in Fine Aggregate on Strength of Mortar BS 1881 Methods of Testing Concrete BS 3148 Methods of Test for Water for Making ConcreteBS 4482 Hard Drawn Mild Steel Wire for the Reinforcement of Concrete BS 4483 Specification for Steel Fabric for the Reinforcement of Concrete BS 4449 Specification for Carbon Steel Bars for Reinforcement of Concrete ISO 4012 Determination of Compressive Strength of Test Specimen2.1.10 Marine CoatingEN ISO 12944:1998 – Paints & Varnishes – Corrosion Protection of Steel Structures by protective paint system (parts 1 – 8) ISO 20340:2009 Paints and varnishes – Performance requirements for protective paint systems for offshore and related structuresISO 15741 Paints and varnishes-Friction-reduction coatings for the interior of on- and offshore pipelines for non-corrosive gases2.1.11 Other specificationBritish Gas BGC/PS/CM1, BGC/PWS/CM2GAZ de France R 09NACE RP 0181NF A 49-706TS 5140TS 5139, 2.2 Lining 2.2.1 Epoxy Lining AWWA C210: Liquid-Epoxy Coating Systems for the Interior and Exterior of Steel Water Pipelines API RP512 or NFA 49-709 Internal can be epoxy 80 micronsTS EN 10289NFA 49708 Recommended Practice for Internal Coating of Line Pipe2.2.2 Bitumen Lining DIN 30673 Bitumen coatings and linings for steel pipes, fittings and vesselsUNI-ISO 5256/87 STANDARD-BITUMEN COATING2.2.3 Cement Mortar Lining AS/NZS 1516 Cement Mortar Lining of Pipelines In SituAWWA C203-02: Coal-Tar Protective Coatings & Linings for Steel Water Pipelines, Enamel & Tape, Hot-pap. (Incl. add. C203a-99) AWWA C205-00: Cement-Mortar Protective Lining and Coating for Steel Water Pipe- 4 In. (100 mm) and Larger-Shop applicationAWWA C602 Standard for Cement-Mortar Lining of Water Pipelines - 4 inch (100 mm) and Larger - In Place2.2.4 Shop Cement Lined PipingAWWA C205,C104,C602DIN 2614British Standard BS 534British Petroleum GS 106-1Shell DEP 30.48.30.31-Gen.Saudi Aramco 01-SAMSS-005KNPC ENG STD 87C1API RP 10E 2.2.5 Plastic Lined ASTM D4894 PTFE (Polytetrafluorethylene)ASTM D3307 PFA(Perfluoroalkory)ASTM D3222 PVDF(Polyvinyledenefluorid)ASTM D4101 PP(Polypropylene)BS 6374-2 Lining of equipment with polymeric materials for the process industries - Part 2: Specification for lining with non-sheet applied thermoplasticsBS 6374-3 Lining of equipment with polymeric materials for the process industries - Part 3: Specification for lining with stoved thermosetting resinsBS 6374-5 Lining of equipment with polymeric materials for the process industries - Part 5: Specification for lining with rubbersPipe Coating ProductsFusion Bonded Epoxy – Fusion Bond Epoxy is a powder epoxy thermosetting coating applied for anticorrosion protection to steel pipelines. The pipe is first blast cleaned and heated. Then epoxy powder is spray applied by electrostatic guns to melt and form a uniform layer that hardens within a minute from application. Utilizing industry accepted materials supplied by manufacturers such as 3M, DuPont, and Valspar, the facility can apply FBE in a wide range of thickness to cost effectively meet any project specifications.Fusion Bonded Epoxy with Abrasion Resistance Overcoating (FBE/ARO) – Utilizing two completely separate powder systems, the facility can produce FBE with an ARO at unprecedented processing speeds using industry accepted materials such as 3M 6352, DuPont 7-2610, and Lilly 2040.Fusion Bonded Epoxy with High Temperature Resistant Overcoating – Utilizing two completely separate powder systems, the facility can produce FBE with a high operating temperature resistant overcoating such as DuPont’s Nap-Gard Gold and 3M’s 6258.Fusion Bonded Epoxy with Zap-Wrap Overcoating – The facility is capable of processing line pipe with connections and of applying the Zap-Wrap abrasion resistance overcoating to the ends of each pipe. Three Layer Polyethylene (3LPE)To improve anticorrosion performance and adhesion, an additional layer of epoxy primer is sprayed onto pipe surfaces prior to the adhesive layer and Polyethylene top layer application. Three Layer Polyethylene is suitable for service temperatures from 60°C to 80°C (85°C peaks). Typical coating thickness is from 1-2 mm to 3-5 mm.Three Layer Polypropylene (3LPP)If a wider service temperature range and high stiffness is required, adhesive and top layers, applied over primer layer, are based on polypropylene instead of polyethylene. Three Layer Polypropylene is suitable for service temperatures up to 135 °C (140°C peaks). Typical coating thickness is from 1-2 mm to 3-5 mm.Three Layer Polypropylene and Polyethylene Three Layer applications involve a thermoplastic coating applied to steel pipelines as a form of anticorrosion protection. This mechanical resistance is appropriate when the risk of particularly severe coating damages exist. The Three Layer process involved several steps. First, the pipe surface is blast cleaned to remove any external residue from the mill or storage. It is then heated and sprayed with a Fusion Bond Epoxy (FBE) primer followed by the application of an adhesive copolymer and polyolefin polymers that are wrap extruded, one over the other.Centrifugal Cement Lining of mild steel pipes of varying lengths and diameters. The size range of our Rutherford plant is 100NB-3200NB in up to 12 meter lengths, all made to the AS1281 standard.Cement types include:•General Purpose (GP)•Sulphate Resistant (SR)•Calcium Aluminate•Seal Coat over cement for harsh environmentsAll linings are applied to AS1281-2001 for lining thickness and tolerances. Linings can be applied to any thickness to suit existing pipe internal diameters.Field applied products3M: SK 134, SK6233, SK6352 Toughkote, SK 314, SK 323, SK 206N, SK 226N, SK 6251 DualKote SK-6171, SK 206P, SK226PDuPont: 7-2500, 7-2501, 7-2502, 7-2508, 7-2514, 7-2803, 7-2504 Nap Gard Gold 7-2504Nap Rock: 7-2610, 7-2617 FBE PowdersDuPont: Repair Kits; 7-1631, 7-1677, 7-1862, 7-1851DuPont Internal Coatings: 7-0008, 7-0010, 7-0014, 7-0009SGR, 7-0009LGR, 7-2530, 7-2534, 7-2509Akzo Nobel: FBE - Fusion Bond EpoxyDenso: 7200, 7900 High Service Temperature CoatingsHeat Shrink SleevesPatch SticksHeresite Protective Coatings

300mm diameter steel pipe