- Contact Person : Mr. Chow Robin

- Company Name : Zhongyou Kingsun International Economic & Trading Co., Ltd.

- Tel : 0086-21-60405576

- Fax : 0086-21-60405590

- Address : Shanghai,Shanghai,Huangxing Road 2077, Yangpu

- Country/Region : China

- Zip : Zip 200433

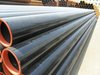

API 5L SSAW pipe

1. Line PipesAPI 5L PSL1/PSL 2 Line Pipe: Gr. B X42, X46, X52, X56, X60, X65, X70, X80/BM.X42M,X46M,X52M,X60M,X65M,X70,X80MISO 3183-1/2 Petroleum and Natural Gas Industries-Steel Pipe for Pipelines Transportation System-L240M,L290M,L320M,L360M,L390M,L415M,L450M,L485M,L555M,L690MISO 3183-3 Petroleum and Natural Gas Industries Steel Pipe for Pipelines Transportation System -L245NC / L245NCS,L290NC / L290NCS, L360NC / L360NCS, L290MC / L290MCS, L360MC / L360MCS, L415MC / L415MCS, L450MC / L450MCS, L485MC / L485MCS, L555MC AS2885 Pipelines-Gas and liquid petroleum Part 1: Design and Construction BS 3601-1 Carbon steel pipes and tubes with specified room temperature properties for pressure purposes BS 3602-2 Specification for steel pipes and tubes for pressure purposes: carbon and carbon manganese steel with specified elevated temperature properties. Part 2: Submerged arc welded tubes BS 6323 Seamless and welded steel tubes for automobile mechanical and general engineering purposes. Part 1: General requirements. Part 7: Specific requirements for submerged arc welded steel tube CSA Z245.1 Steel PipeDIN 2470-1 Steel gas pipelines for permissible service pressures up to 16 bar DIN 2470-2 Steel gas pipelines for permissible service pressures exceeding 16 bar EN 10208-1:2009, Steel pipes for pipelines for combustible fluids - Technical delivery conditions - Part 1: Pipes of requirement class A.EN 10208-2:2009, Steel pipes for pipelines for combustible fluids – Technical delivery conditions – Part 2: Pipes of requirement class B. L245MB,L290MB,L320MB,L360MB,L390MB,L415MB,L450MB, L485MB,L555MBEN 10208-3 Non alloy and alloy fine grain steel tubes EN ISO 21329:2004, Petroleum and natural gas industries - Pipeline transportation systems - Testing procedures for mechanical connections (ISO 21329:2004). ISO 10543:1993, Seamless and hot-stretch-reduced welded steel tubes for pressure purposes - Full peripheral ultrasonic thickness testing. ISO 21329:2004, Petroleum and natural gas industries - Pipeline transportation systems - Testing procedures for mechanical connections. - 1st edition. EEMUA Publ 203:2004, Guide to the Application of ISO 3183 Parts 2 (1996) and 3 (1999) Petroleum and Natural Gas Industries - Steel Pipes for Pipelines - Technical Delivery Conditions. NACE MR 0175/ISO 15156-2 Petroleum and Natural Gas Industries – Materials for Use in H2S Containing Environments in Oil and Gas Production. Part 2. Cracking resistant Carbon and Low Alloy Steels, and the Use of Cast Irons. NACE TM 0177 Laboratory Testing of Metals for Resistance to Sulfide Stress Cracking in Hydrogen Sulfide (H2S) Environments NACE TM 0284 Standard Test Method - Evaluation of Pipeline and Pressure Vessel Steels for Resistance to Hydrogen-Induced Cracking DEP 31.40.20.30-Gen LINEPIPE FOR USE IN OIL AND GAS OPERATIONS UNDER NON-SOUR CONDITIONS(AMENDMENTS/SUPPLEMENTS TO API SPEC 5L) DEP 31.40.20.31-Gen LINEPIPE FOR USE IN OIL AND GAS OPERATIONS UNDER SOUR CONDITIONS(AMENDMENTS/SUPPLEMENTS TO API SPEC 5L) DEP 31.40.20.35-Gen Line pipe for non-critical service (amendments/supplements to ISO 3183-1) DEP 31.40.20.37-Gen Linepipe for critical service (amendments/supplements to ISO 3183-3) DEP 31.40.40.38-Gen Hydrostatic pressure testing of new pipelines DEP 31.40.60.11-Gen Pipeline leak detection DEP 31.40.60.12-Gen Pipeline Repairs (supplements to ANSI/ASME B31.4 and B31.8) DEP 61.40.20.30-Gen Welding of pipelines and related facilities (amendments/supplements to ANSI/API STD 1104) DEP 31.40.50.30-Gen Precommissioning of pipelines NF A 49-112-Plain end seamless hot rolled tubes GOST 8731-87 seamless hot-deformed steel pipes-DIN 1629,ASTM A106BGOST 8732-78 - seamless hot-deformed steel pipes,manufactured on the outside diameter, wall thickness and length. EN 10220 DIN 1630 High-performance seamless circular - Seamless circular unalloyed steel tubessubject to special requirements - EN 10220 DIN 1629GOST 20295:1985, Steel welded pipes for main gas-and-oil pipelines Specifications- K56,K60,K65GOST R ISO 10124:1999, Seamless and welded (except submerged arc-welded) steel tubes for pressure purposes - Ultrasonic testing for the detection of laminar imperfections. GOST R ISO 10332:1999, Seamless and welded (except submerged arc-welded) steel tubes for pressure purposes. Ultrasonic testing for the verification of hydraulic leak-tightness. GOST R ISO 10543:1999, Seamless and hot-stretch-reduced welded steel tubes for pressure purposes - Full peripheral ultrasonic thickness testing. GOST R ISO 3183:2010, Petroleum and natural gas industries - Steel pipe for pipeline transportation systems. - 2nd edition.IPS-M-PI-190 Material And Equipment Standard for Line PipeKOC-MP-018 KOC Standard for Seamless Pipe to API 5LKOC-MS-001 Part 1 Kuwait Material Specification Line Pipe for Sour ServiceNRF-001-Pemex-2007 Steel Piping for Hydrocarbon Collections and TransportationRP 43-1 Onshore Transmission Pipelines to BS 8010 NFA 49-211/ NFA 49-411 TUE 220,TUE 250,TUE 275,TUE 290,TUE 320,TUE 360,TUE 415,TUE 450API 5L: TUBOS PARA CONDUÇÃO DE PRODUTOS PETROLÍFEROS.API 5LX: TUBOS PARA CONDUÇÃO DE PRODUTOS PETROLÍFEROS COM EXIGÊNCIAS ESPECIAIS2. Pipe for General Uses BS 2059 Part I & II Gr. 320, Gr. 360BS 3601 Steel Pipe and Tubes for Pressure Proposes Carbon Steel: Ordinary Duties- Gr. 360,Gr. 430, EN 10220 Seamless and welded steel tubes. EN 10224 Steel pipes, joints and fittings for the conveyance of aqueous liquids including potable water 3. Structural Pipe ASTM A53 A/B 4.Submarine (Offshore) Pipeline SystemDNV OS-F101 Submarine Pipeline Systems-SAWL 245,SAWL290,SAWL 320,SAWL 360,SAWL 415,SAWL 450,SAWL 485,SAWL 555,AS 2885-1:1997AS 2885-2:2002, AS 2885-3:2001, AS 2885-4:2003, AS/NZS 2885-5:2002, ASME B31.4:1998, ASME B31.8:2000,BS 8010-1:1989, BS 8010-2.8:1992,BS 8010-3:1993, Brizil Standards:NBR 5580NBR 5590NBR 6591

API 5L SSAW pipe